In accordance with the requirements of the Clean Production Promotion Law of the People's Republic of China, the Interim Measures for Clean Production Audit and the Notice on the Release of the 2000 List of the Key Enterprises for Clean Production Audit in Anhui Province, we hereby make the following public announcement on the basic conditions of our company before the audit and the status of pollutant generation and discharge, and invite supervision of the public on the implementation of clean production audit in our company.

Company name: SKSHU Paint Co., Ltd.

Legal representative: Fang Guoqin

Address: Jing Si Road, Chemical Industrial Zone, Mingguang City

As prescribed in the Notice on the Release of the 2000 List of the Key Enterprises for Clean Production Audit in Anhui Province issued by the Anhui Provincial Department of Ecology and Environment, SKSHU Paint Co., Ltd. is a key enterprise subject to category-three clean production audit (enterprises emitting toxic and harmful substances in production) in Anhui Province for the year 2020. Information concerning the pollutant generation, treatment facilities and emission progress of our company, the concentration of emissions and total amount of hazardous chemicals compliant with emission standards as well as the measures taken to prevent and control environmental risks are as follows.

1. Wastewater

(1) Wastewater generation and treatment

The wastewater of the plant mainly includes equipment cleaning wastewater, concentrated water for pure water preparation, workshop floor cleaning wastewater, water curtain wastewater, recirculating cooling wastewater, boiler wastewater, domestic sewage, instrument cleaning wastewater, initial rainwater. Canteen wastewater is pretreated by grease trap and then pretreated by septic tank together with domestic wastewater, and then transported to Chengdong Wastewater Treatment Plant in Mingguang City through special open pipe after being treated by self-built comprehensive wastewater treatment station in the plant together with equipment cleaning wastewater, concentrated water for pure water preparation, workshop floor cleaning wastewater, water curtain wastewater, recirculating cooling wastewater, boiler wastewater, instrument cleaning wastewater and initial rainwater.

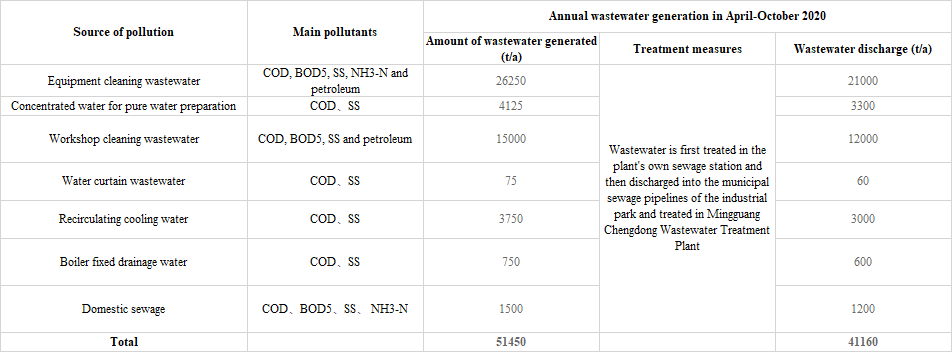

The specific information concerning the generation and discharge of wastewater in the plant site is shown in the following table.

Table 2-11 List of wastewater generation from April to October 2020

(2) The wastewater treatment that meets the standard

According to the test report of Anhui Jiyue Environmental Testing Co., Ltd. dated March 25-26, 2020 (see annex for the test report), the summary analysis of wastewater data of SKSHU Paint Co. is shown in the following table:

Table 2-12 Statistical table of wastewater testing results Unit:mg/L

As the testing result shows, the concentration of the major pollutants in the pretreated wastewater discharged by SKSHU Paint Co., Ltd. Complies with the receiving standard of Mingguang City East Sewage Treatment Plant.

The project’s wastewater COD emission is 4.3107t/a and ammonia nitrogen emission is 0.0137t/a. The wastewater is treated by the wastewater treatment station in the factory and then received by Mingguang Chengdong Wastewater Treatment Plant for centralized treatment, and the total amount is balanced in the wastewater treatment plant.

2、Exhaust gas

(1) Exhaust gas generation and its treatment

The exhaust gas emitted by SKSHU Paint Co., Ltd. mainly includes the exhaust gas of the colorful paint and putty powder exhaust gas of the all-in-one workshop; the exhaust gas of the latex paint workshop and stone texture paint workshop; the exhaust gas of the paint workshop of the polyurethane waterproofing workshop and water-based adhesives laboratory; the laboratory exhaust gas of the canning sample room; the exhaust gas of the waterproofing membrane workshop and the tank asphalt modification workshop and production line workshop; the exhaust gas of the heat-conducting oil furnace; the exhaust gas of the steam boiler; the exhaust gas of the sewage treatment station.

During the acceptance monitoring period, the maximum emission concentration of particulate matter in the exhaust gas of the colorful paint workshop and putty powder exhaust gas of the all-in-one workshop, a coating production and matching construction project of SKSHU Paint Co., Ltd., is <20mg/m3, and the maximum emission rate is 0.187kg/h, both of which are compliant with the level-two emission standards of the Standards on the Emission of Atmospheric Pollutants (GB16297-1996); the maximum emission concentration of volatile organic compounds (VOC) is 0.312mg/m3 and the maximum emission rate is 5.79×10-3kg/h, both of which are compliant with the emission limits of the II time period for the manufacture of paints, inks, pigments and similar products (C2640) in Table 1 of the VOC Emission Standards Part 6: Organic Chemical Industry of Shandong Province. The maximum emission concentration of particulate matter in the latex paint workshop and stone texture paint workshop is <20mg/m3 and the maximum emission rate is 0.294kg/h, both of which are compliant with the level-two emission standards of the Standards on the Emission of Atmospheric Pollutants (GB16297-1996); the maximum emission concentration of VOC is 0.320mg/m3 and the maximum emission rate is 9.30×10-3kg/h, both of which are compliant with the emission limits of the II time period for the manufacture of paints, inks, pigments and similar products (C2640) in Table 1 of the VOC Emission Standards Part 6: Organic Chemical Industry of Shandong Province. The maximum emission concentrations of particulate matter and VOC in the polyurethane waterproof coating workshop and the water-based adhesive workshop and laboratory are respectively 7.3mg/m3 and 0.310mg/m3, both of which are compliant with the requirements of Table 5: Special Emission Limits of Atmospheric Pollutants under the Pollutant Emission Standards of the Synthetic Resin Industry (GB31572-2015). The maximum emission concentration of particulate matter in the laboratory exhaust gas of the canning sample room is <20mg/m3 and the maximum emission rate is 0.160kg/h, both of which are compliant with the level-two emission standards of the Standards on the Emission of Atmospheric Pollutants (GB16297-1996); the maximum emission concentration of VOC is 0. 248mg/m3 and the maximum emission rate is 3. 90×10- 3kg/h, both of which are compliant with the emission limits of the II time period for the manufacture of paints, inks, pigments and similar products (C2640) in Table 1 of the VOC Emission Standards Part 6: Organic Chemical Industry of Shandong Province. In the the exhaust gas of the waterproofing membrane workshop and the tank asphalt modification workshop and production line workshop, no benzo(a)pyrene has been detected; the maximum emission concentration of particulate matter is 5.5mg/m3 and the maximum emission rate is 0.230kg/h; the maximum emission concentration of non-methane total hydrocarbon is 0.80mg/m3 and the maximum emission rate is 0. 033kg/h; the maximum emission concentration of asphalt fume is 8.5mg/m3 and the maximum emission rate is 0.356kg/h, all of which are compliant with the emission limits of the II time period under the Emission Standards of Atmospheric Pollutants in the Waterproofing Membrane Industry (DB11/1055-2013). The maximum emission concentrations of particulate matter, sulfur dioxide and nitrogen oxides in the exhaust gas of heat-conducting oil furnace are respectively 5.9mg/m3, 4mg/m3 and 31mg/m3, all of which are compliant with the emission limits of gas boilers in Table 3: emission limits of atmospheric pollutants under the Emission Standards for the Atmospheric Pollutants of Boilers (GB13271-2014). In the exhaust gas of steam boilers, no sulfur dioxide has been detected, and the maximum emission concentrations of particulate matter and nitrogen oxides are respectively 6.3mg/m3 and 26mg/m3, both of which are compliant with the emission limits of gas boilers in Table 3: emission limits of atmospheric pollutants under the Emission Standards for the Atmospheric Pollutants of Boilers (GB13271-2014). The maximum emission rates of ammonia and hydrogen sulfide in the waste gas of the sewage treatment station are respectively 0.014kg/h and 4.56×10-3kg/h, both of which are compliant with the emission limits set out in Table 2 of the Emission Standards for Odor Pollutants (GB14554-1993).

3、Noise

(1) Noise generation and prevention & control

The noise sources in the plant site mainly include pulping machine, paint mixing kettle, mixing machine, dispersing machine, enamel kettle, rotary drying loading machine, oil-free air compressor, heating circulation pump, special grinding machine, seam welder, flanging machine, one-piece machine, canning machine, drying machine, iron cutting machine, press machine, air compressor, uncoiling device, traction device, tyre drying device, embossing device, extruder, edge cutting device, asphalt transfer pump, mixing tank, asphalt pump, machine oil pump, naphthenic oil pump, tumbling machine, heavy duty sanding machine, primer fine sanding machine, laminating and cutting machine, coating machine, glue mixing machine, laminating cold press and other processing machines. The company has already taken a host of vibration damping, noise elimination and sound insulation measures in the plant site to reduce noise pollution.

(2) Noise management for compliance with standards

Table 2-13 Statistical table of noise detection results

The results of daytime and nighttime monitoring around the plant boundary are within the standard limits and compliance with the class 3 standard in the Environmental Noise Standards for Areas within the Plant Boundary of Industrial Enterprises (GB12348-2008).

4、Solid waste

The solid waste generated by the project mainly includes the filter residue of emulsion paint and polyurethane waterproofing coating, the trimmings, defective products and waste welding films produced in can-making, the trimmings and unqualified products generated during the production of waterproofing membrane, the waste sanding paper, trimmings and waste packaging materials generated during sample production, ion exchange resin and reverse osmosis membrane generated during pure water preparation, dust collection, waste activated carbon and UV lamp, and water curtain cleaning paint sludge produced by waste gas treatment equipment, sludge produced by wastewater treatment equipment, packaging materials generated by the use of raw and auxiliary materials, oiled rags and gloves generated by equipment maintenance, as well as domestic waste generated in factory employees’ daily life and office work, and chemical waste liquid produced by canteen food waste (slop) and product inspection.

(1) Domestic waste

The amount of domestic waste generated by factory workers is about 20t per year. The domestic waste is bagged and collected by the sanitation department and then sent to the sanitary landfill.

(2) General solid waste

1)Paint filter residue. General industrial solid waste, amount generated 3.6t/a, partly reused in production and partly treated in the sewage treatment station at the plant site.

2)Trimmings and scraps. General industrial solid waste, amount generated 300t/a, disposed of by Anhui Shengxi Luyuan Environmental Protection Technology Co., Ltd.

3)Waste welding piece. General industrial solid waste, amount generated 13t/a, disposed of by Anhui Shengxi Luyuan Environmental Protection Technology Co., Ltd.

4)Coil trimmings and unqualified products. General industrial solid waste, amount generated 0.3t/a, disposed of by Anhui Shengxi Luyuan Environmental Protection Technology Co., Ltd.

5)Sample trimmings. General industrial solid waste, amount generated 3.5t/a, disposed of by Anhui Shengxi Luyuan Environmental Protection Technology Co.

6)Waste sanding paper. General industrial solid waste, amount generated 13t/a, cleaned and transported by the sanitation department of the industrial park.

7)Waste packaging materials. General industrial solid waste, amount generated 0.1t/a, cleaned and transported by the sanitation department of the industrial park.

8)Waste reverse osmosis membrane. General industrial solid waste, amount generated 0.5t/a, recycled by the supplier.

9)Dust collected by the dust collection equipment in the comprehensive workshop. General industrial solid waste, amount generated 40t/a, collected and reused in production

10) Dust collected by the dust collection equipment in the polyurethane waterproofing coating workshop. General industrial solid waste, amount generated 15t/a, disposed of by Anhui Shengxi Luyuan Environmental Protection Technology Co., Ltd.

11) Dust collected by the dust collection equipment in the water-based adhesive workshop. General industrial solid waste, amount generated 8t/a, disposed of by Anhui Shengxi Luyuan Environmental Protection Technology Co., Ltd.

12) Dust collected by the dust collection equipment in the sample room. General industrial solid waste, amount generated 0.1t/a, disposed of by Anhui Shengxi Luyuan Environmental Protection Technology Co., Ltd.

13) Biochemical sludge. General industrial solid waste, amount generated 144t/a, disposed of by Anhui Shengxi Luyuan Environmental Protection Technology Co., Ltd.

14) Waste raw and auxiliary materials packaging. General industrial solid waste, amount generated 1t/a, disposed of by Anhui Shengxi Luyuan Environmental Protection Technology Co., Ltd.

15) Paint residue. General industrial solid waste, amount generated 0.7t/a, disposed of by Anhui Shengxi Luyuan Environmental Protection Technology Co., Ltd.

(3) Hazardous waste

1) Waste UV lamp. Hazardous waste, category HW29, code 900-023-29, amount generated 0.005t/a, disposed of by Anhui Chaoyue Environmental Protection Technology Co., Ltd.;

2) Waste ion exchange resin. Hazardous waste, category HW13, code 900-015-13, amount generated 20t/a, disposed of by Anhui Chaoyue Environmental Protection Technology Co., Ltd.;

3) Waste activated carbon. Hazardous waste, category HW49, code 900-041-49, amount generated 8t/a, disposed of by Anhui Chaoyue Environmental Protection Technology Co., Ltd.;

4) Hazardous chemical packaging materials. Hazardous waste, category HW49, code 900-041-49, amount generated 2.5t/a, disposed of by Anhui Chaoyue Environmental Protection Technology Co., Ltd.;

5) Inspection waste liquid. Hazardous waste, category HW49, code 900-041-49, amount generated 2.5t/a, disposed of by Anhui Chaoyue Environmental Protection Technology Co., Ltd.;

6) Physical and chemical sludge. The company commissioned Guangzhou Zhongke Testing Technology Service Co., Ltd. to conduct hazardous waste identification on the physical and chemical sludge of sewage treatment, which concluded that the physical and chemical sludge is not a hazardous waste. The waste is hence disposed by Anhui Shengxi Luyuan Environmental Protection Technology Co., Ltd.;

The total area of the temporary storage room is 895.68m2, which is sealed with impermeable concrete to prevent seepage. The hazardous waste is stored in partitions, and the storage room is equipped with a diversion ditch and a water collection well.

Our company has designated a senior executive to oversee work related to environmental protection, with the support of the necessary departments and staff, and formulated a sound environmental management system and an emergency plan to deal with accidents. We conduct the relevant tests on time in strict accordance with the national laws and regulations, strictly manage the storage and disposal of hazardous waste, provide regular training to employees on the knowledge of environmental protection and hazardous waste treatment, and organize relevant practical exercises. The discharge and emission of pollutants are all implemented in compliance with the required standards.

Tel:

Tel: Email:

Email: Address:

Address: